QIDI Q1 Pro reveled! (ad)

This post is sponsored and written by Qidi.

Following the success of the QIDI Smart3, Plus3, and Max3, QIDI Tech is back in 2024 with the Q1 Pro, the first consumer 3D printer with active chamber heating available.

The expert R&D team at QIDI has always been dedicated to creating FDM 3D printers of the highest quality.

The latest FDM 3D printer, the Q1 Pro, adds additional features to the last year's flagship machine, the MAX3, which was a high-speed 3D printer with a large build volume and active chamber heating that makes most high-performance filaments printing available.

Speed and automation

Speed and quality have become the criteria for judging whether consumer 3D printers are up to scratch. The QIDI Q1 Pro has been shortlisted as a high-speed 3D printer due to its impressive print speed of up to 600mm/s and acceleration of 20,000mm/s².

The machine also includes fully automatic leveling with dual sensors, dual Z-axis motor drives, bimetallic nozzles, and a revolutionary active heated chamber system, all of which significantly increase print quality.

Additional functions include vibration correction, power failure replacement, material break/tangle detection, and remote monitoring to improve the user experience.

Basic Functionality Upgraded

The QIDI Q1 Pro is an out-of-box 3D printer without assembly.

Just like other QIDI printers that were introduced in 2023, the Q1 Pro keeps using the Core-XY motion mechanism, which is thought to be optimal for quick printing.

The internal structure is still an all-metal frame with a metal crossbar reinforcement at the bottom. The XY axis is a 10mm hollow optical axis, which is employed in most machines to minimize weight.

However, the Q1 Pro stands out for its dual Z-axis design. The Z-axis is controlled by two independent motors to assure the machine's stability, and it includes an auto-tilt leveling function to avoid discrepancies in left and right heights produced by long-time operation.

Enclosed Active Heated Chamber

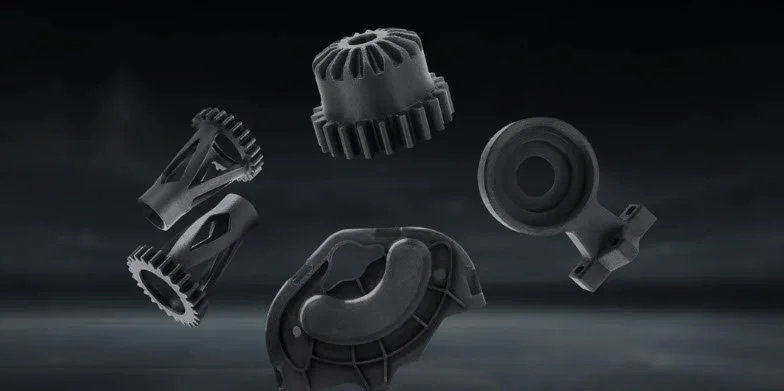

The QIDI Q1 Pro is entirely enclosed and has a separate heater for active heating, which elevates the temperature in the print chamber to 60°C and keeps it. This not only lowers print distortion but also improves adhesion between the model's layers to prevent layer separation. When combined with a hot bed heated to a maximum of 120°, this is quite useful for printing warp-prone materials like ABS and PA. This unique design increases print success rates while also improving print quality.

Example how the heated chamber not only helps with first layer adhesion, but more importantly with mid-print adhesion between layers. Less cracking and deformation of parts with complex materials.

Extruder and nozzle design

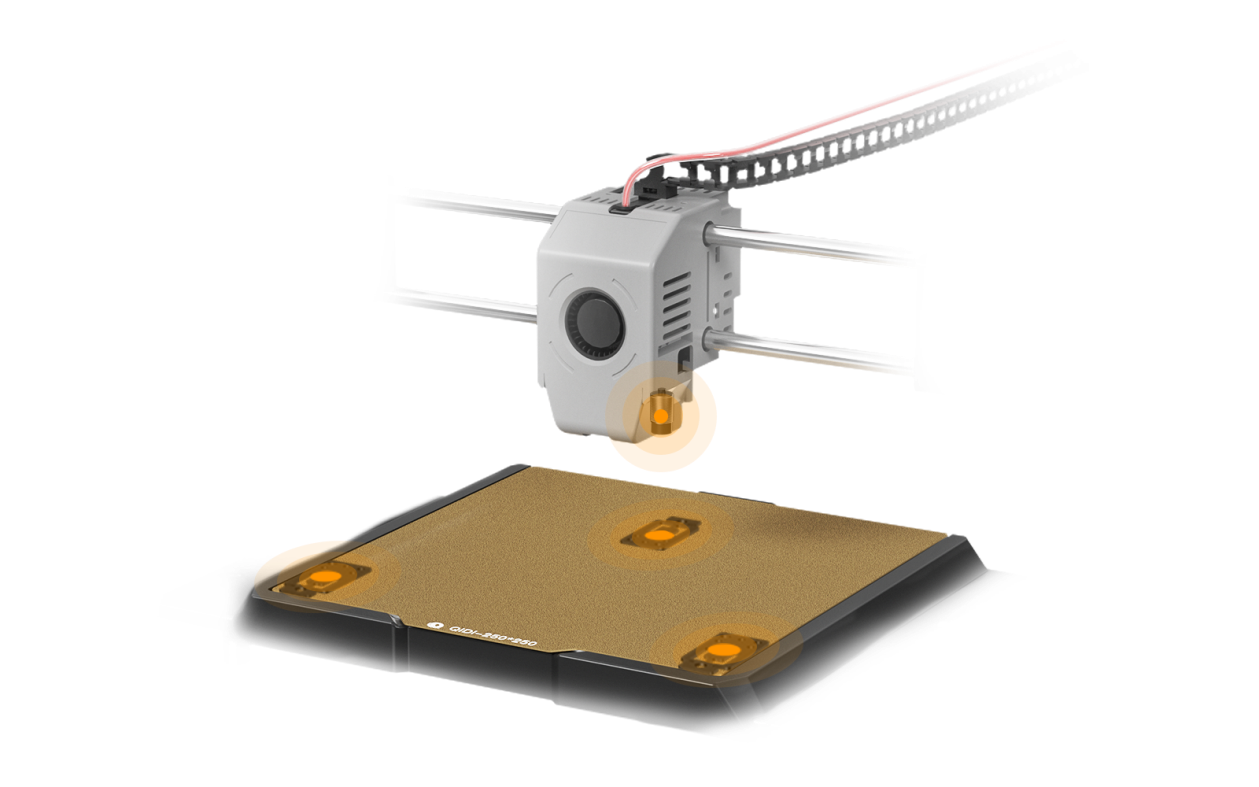

The Q1 Pro utilizes a proximal dual gear direct drive extruder design with a 9.5 : 1 gear ratio to ensure efficient power transfer for fast, accurate and stable filament feeding, which is critical for performing high-speed 3D printing.

Unlike the previous QIDI X series, which came with two sets of hot ends, the Q1 Pro defaults to a 0.4mm bimetallic nozzle with a copper body and a hardened steel tip that can withstand high temperatures of up to 350°C, making it suitable for most of the print materials on the market and eliminating the need to worry about material selection.

Newly upgraded features you won’t believe for the price

The Q1 Pro is equipped with a Filament Run-out Detection with an auxiliary filament sensor above the extruder gear. When the filament run out or a break occurs during printing, the machine will automatically stop printing, effectively avoiding wasting. The front cover of the print head is fitted with a 5015 radial fan for part cooling, which is secured by two plastic clips and magnets in the housing, making it both robust and easy to remove and maintain.

It is worth mentioning that the Q1 Pro has also been upgraded with a Filament Tangle Detection, which is realized by a sensor located on the back side of the machine's chamber. During the printing process, if the material cannot be fed properly due to a tangle, the machine is able to quickly recognize the problem and automatically pause the printing, as well as send out an error alert.

It is interesting that the Q1 Pro is equipped with a Nozzle Cleaning Mechanism that automatically cleans the nozzles before each auto-leveling and start of printing. It integrates waste wiping and collection as well as nozzle cleaning, making this operation even more convenient.

The Q1 Pro also revolutionizes manual leveling with a fully automatic leveling design that ensures a perfect first layer print every time. The principle is based on a dual leveling system. In addition to the proximity switch on the right side of the nozzle, there are three piezoelectric sensors under the hot bed to compensate for Z-axis offsets and complete the automatic leveling.

The Q1 Pro is equipped with a 1080p HD camera that provides users with the ability to monitor the machine remotely. This feature is not often seen in machines in this price range.

With the QIDI Slicer software or mobile app, users can monitor the progress and status of their prints any time any where.

Price and availability

If you are looking for a cost-effective FDM 3d printer with active chamber heating, or the same print speed and excellent print quality as the MAX3, then the Q1 pro will fulfill your needs for a 3d printer.

With a discounted price of just $469, the Q1 Pro is worth your while.

QIDI Q1 Pro Full technical Specifications

Print Volume: 245x245x240mm

Printer Dimensions: 477x467x498mm

Printer Weight: 17kg

Machine Design: Enclosed CoreXY

Z axis design: Dual Independant Lead screw motors

Enclosure material: Plastic

Chassi metarial: Steel

Stepper Motors: 42-48 High-Speed Motor

Print Temperature: Up to 350C

Extruder Gears: Hardened Steel Gears

Extruder transmission ration: 8,9:1

Hot End Design: Ceramic plate heating hot end

Nozzle: Bimetal Nozzle

Nozzle Diameter: 0,4mm

Filament Diameter: 1,75mm

Max Print Speed(travel): 600mm/s

Accelleration: 20 000mm/s2

Rated power: 350W

Interface: 4.3” TouchScreen

Operating system: Windows, MacOS and Linux

Printing Platform: Aluminium substrate heating bed.

Print Plate: PEI Magnetic build plate

Build Plate Temperature: up to 120C

Chamber temperature: 60 C

Cooling: Hot end, Model, Part auxiliary, Motherboard and chamber. All using Closed Loop Control.

Recommended Filament: PLA, ABS, ASA, PETG etc.

Compatible filaments: TPU, PA, PC, Carbon/Glass Fiber etc.

Filament Tange detaction: Yes

Filament Run Out Sensor: Yes

Automatic Leveling: Yes

Input shaper: Yes

Power Loss recovery: Yes

Camera: Yes 1080p with Timelapse

Slicer: QIDI Slicer and 3rd party like Ultimaker Cura, Prusaslicer, OrcaSlicer etc.

Wifi: Yes 2,4Ghz

Onboard storage: 32GB

Processors: Dual-Core Cortex M4 for Motion. Quad-Core 1.55Ghz Cortex-A53 for application and Dual-Core Corext M0+ for extruder.