Choosing 3D Printing Technology for beginners

Choosing 3D Printing technology for your first 3D Printer can be tricky. There are many exciting technologies that all have their own benefits and features.

In this guide we’ll help you understand what those are so you can make the best possible choice entering 3D Printing.

When first starting to look for a 3D Printer you’ll encounter a few different 3D Printing technologies like FDM, FFF, LPD, DLP, SLS and SLA. What does the technologies mean and which ones are suitable for a beginner? Let’s clear things out and go through a few tips for beginners.

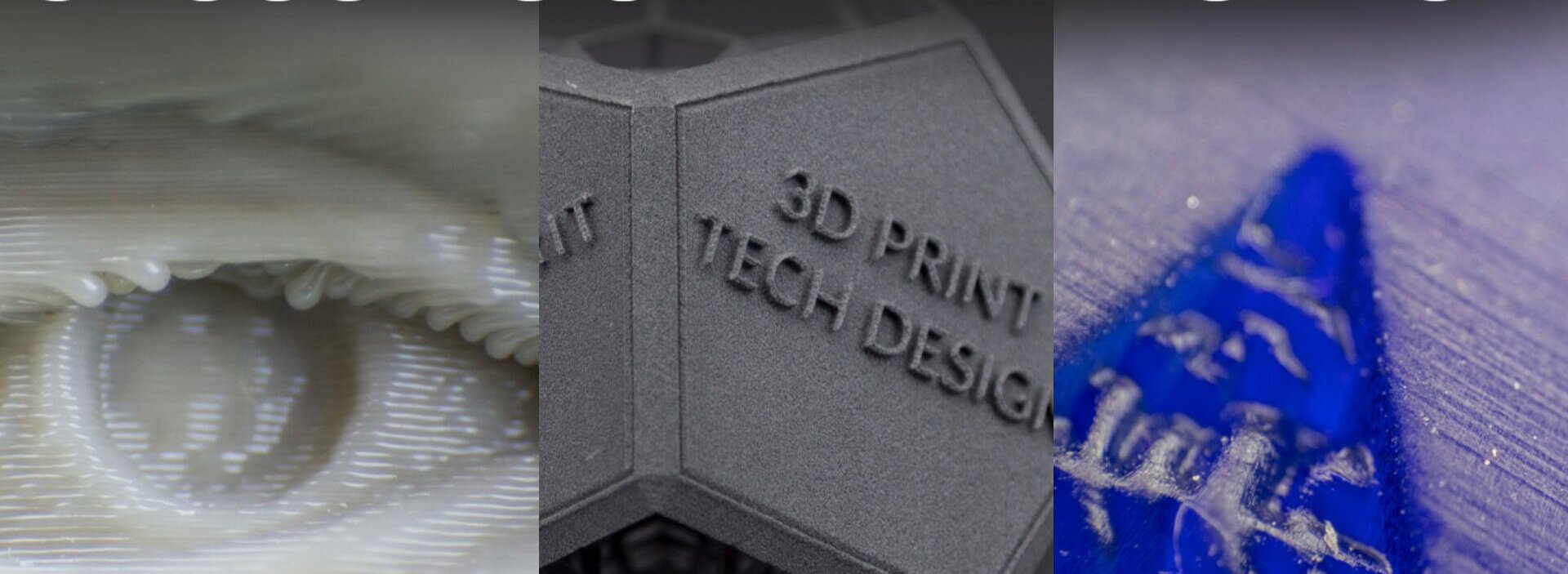

Extrusion, Resin and Powder technologies

Let’s first divide into three main categories of technologies. These all have subcategories that differs slightly, usually because of patents. Further down we’ll list a few of each category for you to check out.

Extrusion (including FDM, FFF and LPD) are the most common 3D Printing technologies for beginners as they were made accessible a few years ago with the RepRap open source projects. This resulted in a incredible price drop and is still among the cheapest 3D Printers you can get.

Subcategories of Extrusion are (among others) FDM, FFF and LPD are all very similar but named differently due to patents and small variations. LPD is for example Zortrax way of separating themselves, but it’s (for a normal user) the same as FFF or FDM.

Extrusion is the technology where a string of plastic filament is being fed through an extruder that melts the plastic and deposits it on a build-plate. The layers are then built on top of each other and results in a 3D model. As with almost all other processes this is a layered process.

Extrusion 3D Printing technology has a few benefits that makes them a fantastic beginner 3D printer. Let’s list a few:

Extrusion 3D Printer benefits:

Very cheap to purchase. The cheapest one’s going at around 100-150$.

Low running costs (if you exclude your time).

Simpler technology – Few high-tech parts.

Wide arrange of features and “steps” in the technology depending on price range.

Can run multiple types of materials – Allowing an user to advance within the same machine, achieving more when more experienced.

“What you see is what you get” – Direct feedback on results.

With the good comes the bad, here’s a few downsides with extrusion technology:

A lot of parameters that affect your print results.

Have a tendency to shrink printing some materials – Leading to failed, loose and warped prints.

Require a lot of hands-on to get great prints (usually higher cost= less hands-on).

Hundreds of suppliers in machines and materials, making it hard to have “finished” settings since every brand of machine and filament work differently together.

Hard to get the best results without trial and error.

Thicker layers and slow. Getting “finished models” is almost impossible.

Usually not the best details.

Hard to dial in more complex materials such as ABS and Nylon.

Should you go for Extrusion 3D Printing?

For most users who want to get into 3D Printing, experience the tools and aren’t sure on exactly what to create, FDM and extrusion printing technology are a great beginner options due to the low investment. There’s tons of help and groups to get inspiration and knowledge from, as well as

You end up learning all the basics that other technologies offer, but at a low investment. Extrusion 3D Printers allows for almost limitless modding and the community is huge and helpful. FDM is the “bit of everything” technology suitable when you’re OK with average results as your prints improve as your understanding does.

Resin 3D Printing Technology

Resin 3D Printers work by curing a resin with UV-light. The light can come from a digital light source (called DLP) or a laser (often called SLA) and although the differ, they both mainly produce the same type of result.

To confuse you even more there’s sub-catagories of SLA that don’t use lasers and therefor alot of machines are called SLA 3D Printers although they don’t really perform like a laser SLA. Confusing? Yes.

One of these technologies is the masked SLA, that uses pixels to separate the light instead of a laser. When referring to DLP below, i’ll include M-SLA in those, as it’s pixel-based.

Often DLP (or M-SLA) cures a layer at a time, but at less resolution due to the LCD screen pixels, while SLA cures lines by drawing with a more accurate laser. The difference can be seen on rounded parts, where DLP are more “pixelated” while laser-SLA looks smoother.

laser SLA is usually more expensive and can be found in machines like Formlabs and Peopoly Moai. DLP (or M-SLA) has become much cheaper and is found on several similar machines like the Anycubic Photon, Wanhao D7, Micromake L2 and the newly released Prusa SL1.

Resin 3D Printing technology benefits:

High resolution 3D Printing – often details as small as 0,025mm.

Beautiful surfaces with almost invisible layers.

Homogeneous prints that can result in glass/transparent prototypes.

Fairly reliable.

Wide range of colors and simple self-coloring with special resin ink.

Parts can be painted, sanded, grinded, processed fairly easily.

Materials that are recognizeble; ABS, Nylon, TPU and similar.

There are a few drawbacks with Resin 3D Printer technology that easily can be forgotten for anyone recommending them for a beginner:

Sticky and messy – Handling resin needs to be done with gloves, and it sticks to everything!

Post processing not an option, it’s a must. You need to dissolve unused resin and remove supports on your model. You should also UV-cure the print to make sure it’s strong.

If you need fine-tuning it’s quite time consuming.

It’s a bit smelly and can cause headaches if used next to your desk all day.

Higher printing costs (compared to FDM)

Materials are by nature more sensitive for UV-light and aren’t great for “use” in the long run.

Fewer available materialvariations since they are limited to resins.

Who should start with Resin 3D Printing technology?

In short Resin 3D Printers should be considered when you really want to create high-detail 3D prints such as miniatures, figurines and precision parts and details. Since it allows for small details in high resolution, that really is what you should be willing to do.

larger parts in resin are of course doable, but very time consuming and gets a bit expensive.

Resin printers are great for adding details for cosplay parts, but larger items like helmets and armor should be made with Extrusion type printing if you’re looking into cosplay.

Be aware that resin printing involve a lot of post processing and almost all models require support materials to be removed by hand after finishing a print.

Powder based 3D Printing technology

Let me start by saying that Powder 3D Printing technologies are not cheap, but they do however start to come down in price and if you’re a company or school they could definitely be something to look at as they offer some great advantages.

Powder 3D Printing technology could be compared to a sandbox, adding a thin layer of sand and hardener (by melting or gluing) the grains together on select places. Then a new layer is added and the procedure continues (also sticking to the previous layer).

Powder 3D Printing occur in SLS (selective laser sintering) where materials like nylon powder is cured into shape. SLS offers great advantages but of course comes at a cost. In general it’s quite simple process, but require higher running costs and maintenance.

Benefits of using Powder based 3D printing technologies:

No need for support – Parts are supported by the powder around them.

Free design inside the volume due to the powder support.

High strength parts in various materials – Comparable to real-world production parts.

Great matte finish and layers are less visible compared to extrusion.

Temperature resistant parts – Often over 150-200C degrees resistance in the parts.

Again, with the good comes a few drawbacks:

High production costs with printing and maintenance costs

Some warping occurs in different materials

Slow printing process – Distributing new layers takes time.

Moisture/environmentally sensitive.

Often a cleaning process removing the unused powder

Usually a messy and dusty-post processing – Could require air filtration or mask/gloves.

With that said, powder based technology obviously is not for the generic beginner and I think we should focus a bit on a few typical users and interest and match it with a technology.

If you’re curious about powder based 3D Printer I went to Sinterit to check out their entry-level SLS 3D Printer “Lisa” in this video:

Matching 3D Printing Technologies to different areas

Cosplay (Helmets, armor, swords, replicas) – FDM/FFF Extrusion 3D Printing

Modelers (trains, planes and similar) – SLA/DLP Resin 3D printers that can handle the parts

RC Planes/Cars/Drones – FDM/FFF Extrusion 3D Printing

Home improvement – Could be both depending on the quality you’re looking for

School/Education of K1-9 – FDM/FFF Extrusion 3D Printing – Since it’s more accessible and safer in terms of chemicals and laser/light.

Dental – SLA/DLP Resin 3D printers

GoPro/Camera Gear – FDM/FFF Extrusion 3D Printing

Warhammer/Roleplay/Figurines –

Jewelry – SLA Resin 3D printers preferably

Engineering – Both, depending on part size, precision and functionally

Wondering what technology you should look into for your project? Comment down below or contact us!

3D Printers matched with 3D printing Technology

Here’s a few options of 3D Printers in no particular order, that are great options for each category. If we’ve made a review of one It’s linked under the image!

Extrusion based 3D printing Technology options

The following machines are my recommendation for great 3D printers in different price ranges related to FDM, FFF and LPD.

Flashforge Adventurer 3

A great beginners 3D Printer that is easy to use and to maintain. Perfect for printing PLA, comes with a heated bed.

Creality Ender 3 Pro

A great beginners machine for those that are a bit more handy. This machine has become really popular lately.

Resin 3D printing Technology options

The following machines are my recommendation for great 3D printers when considering SLA and DLP as a beginner.

ELEGOO Mars 2 Mono

The Eleegoo Mars 2 is a fantastic entry machine into resin 3D Printing with good quality, large user community and loads of compatible resins.

Make sure you reach out if you’re wondering what technology I’d recommend for your use!

Explain a bit about your skill level and what you’d like to do!