BCN3D Metal 3D Printing

Now you can 3D Print metal on BCN3D Epsilon 3D Printers. BASF 3D Printing materials enables a full on metal 3D Printing option for BCN3Ds FDM 3D Printers.

Metal 3D Printing Pack

The new Metal Pack for BCN3D Epsilon 3D Printers is a addon-kit that allows you to extrude filaments for metal 3D Printing. The machine won’t actually extrude solid metal, but a part ready for processing. More on that further down.

The new kit is set to cost 1.099,95€ excluding taxes, and includes everything you need to start 3D Printing metal:

Ultrafuse® 316L (3kg spool)

Ultrafuse® 17-4PH Filament (3kg spool)

Magigoo 316L adhesion glue

Two BCN3D M-Hotends for Metal

BCN3D Brass Wipers

Software profiles for BCN3D Stratos slicer

3D Printed Stainless Steel Materials

Ultrafuse 17-4PH final part is an incredible stainless steel print for serious hardness and mechanical strength.

Ultrafuse® 316L creates type 316L stainless steel parts through metal-polymer composite.

3D Printing in metal can be used in countless scenarios, but a few highlighted ones are: Tooling Jigs, fixtures, series production and of course Functional parts and prototypes.

How A FDM 3D Printer Prints Metal

Looking at the price of the Metal Pack and the BCN3D Epsilon printers themselves it sounds like an impossible combination.

To fully understand why this is not the case, we have to look at the process itself.

Installing the Metal Pack basically enables extrusion of metal-polymer composite filament.

This filament can be described as plastic containing a high percentage of metallic powder.

Your BCN3D Printer can extrude this material similar to ABS, PLA or PA prints.

These are not pure metal 3D prints and have no strength. They have to be processed.

Metal 3D Printing Process

Step 1. 3D Printing

3D Print

The first step, 3D Printing is what you can do with your BCN3D Epsilon 3D Printer. Or, any other 3D Printer that can extrude BASF Ultrafuse materials.

This is just the “Green part”, a plastic model with binder, metallic powder and plastic inside.

Step 2. Sintering

Debinding/Sintering

In the second step the printed part is deboned. Depending on material this happes before or during Sintering, which is the process where the metallic powder (inside the filament) is fused together in a special oven.

Basically the metal powder binds (sinters) and becomes a solid part.

Step 3. Post-Processing

Post-Processing

During Sintering, deformation is to be expected. We can assume BCN3Ds slicer does some form of calculation of the deformation, but you usually need to machine down to exact tolerances on vital areas.

This process often includes sanding or sandblasting to create a more shiny surfaces than the sintered model.

Authorized Partners

Step two and three in the Metal 3D Printing process require expensive equipment and processes. It’s nothing regular users (or even professionals) are expected to invest in or handle themselves.

Therefor BCN3D collaborates through Forward AM authorized network of suppliers, instead of selling you the equipment.

This requires you to ship out your “green part” to a supplier and have it processed. These suppliers are scattered around the world and for most BCN3D Customers it should be relatively easy to find a partner.

Thanks to batch processing, suppliers can keep prices down as long as there’s enough circulation.

A great example is 3D Herndon in the US who offers debinding and Sintering Coupons for Ultrafuse 316L parts at $50.

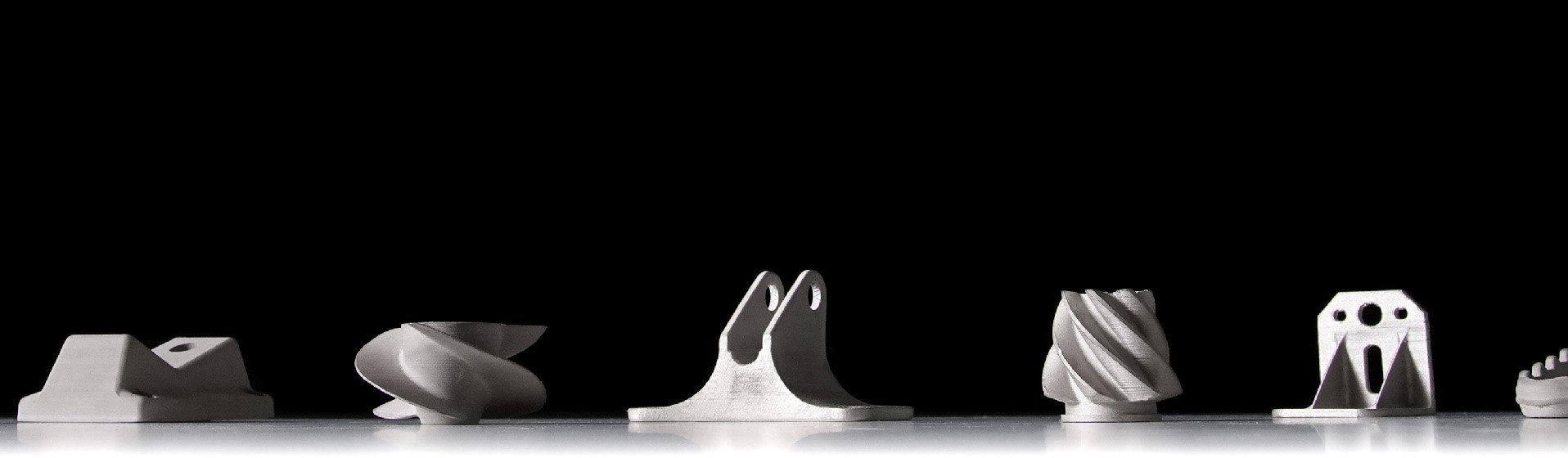

What can you 3D Print with BCN3D Metal Pack?

FDM 3D Printers are generally limited in nozzle size, build size and support-structures. In this article we explain the difference between FDM, SLA and SLS technologies. This means you won’t be able to print the smallest features or the biggest volumes.

A plus with BCN3D Epsilon printers are the dual extruders, which can allow you to print with a support material, allowing for even more complex prints compared to most FDM 3D Printers.

The BCN3D BVOH is a support material apparently compatible with Ultrafuse 316L and 17-4PH. It can be removed in post-processing and helps support structures otherwise only able to be printed with SLS 3D Printing.

Huge benefits

These things considered, you can create fantastic internal structures into parts otherwise impossible to machine with traditional CNC milling or casting.

The ability to create lower infill parts, or just holes inside your structure, makes it possible to reduce weight while maintaining strength and stability.

Sintered, but not processed part.

Drawbacks of filament based Metal 3D Printing

What you can’t expect is perfect surfaces. During the printing, and specially Sintering, the part warps. Things deform slightly.

Although the slicer is fine-tuned to your geometry and the material, warping is still something you have to consider.

Any surfaces with tolerances, such as holes, contact surfaces or precise measurements should be machined in post processing.

This can include drilling out holes or flatting surfaces to an exact specification.

You can however prepare your part for better surface finish before sending it to a partner. Check out Matterhackers guide here.

Learn more and get started with Metal 3D Printing

To get started with Metal 3D Printing you should start by evaluating what you need, and what your budget is.

In some cases it makes sense to go with BCN3D Epsilon 3D Printers and Ultrafuse. A combination that is incredible powerful since you get regular Dual Extruder performance when you don’t need metal Printing.

To get help evaluating you needs, reach out to local BCN3D Resellers.

Ultrafuse product sheets:

More from 3D Print Tech Design

Recognizing that BCN3D Printers are far from the only company that can 3D-print Ultrafuse materials, we will work on explaining metal 3D printing more precise.

We’ll guide you through techniques, how to actually print and what costs are involved. Stay tuned by following social medias and the website.